Introduction:

On September 23, 2022, Senate Bill 972 (SB 972) was signed by the Governor and became effective January 1, 2023. This bill modified the California Retail Food Code (CRFC) to reduce some structural and operational requirements for lower risk sidewalk food vending operations. SB 972 created a new category of Mobile Food Facilities termed Compact Mobile Food Operation (CMFO).

This document provides information on the structural requirements based on the CRFC for CMFOs that handle unpackaged foods. The type of food service for these types of CMFO's is restricted to Limited Food Preparation as defined in the California Retail Food Code Section 113818. Examples of menu items that easily fit within limited food preparation include but are not limited to hot dogs, cut fruit, shaved ice, roasted nuts, popcorn, or churros.

Plan submittal is required for the review of any new CMFO, and plans must be approved before applying for a Health Permit. Use the Plan Submittal Checklist to ensure that all necessary information is included as part of the plan submittal.

- Commissary means a health permitted food facility that services mobile food facilities.

- Compact Mobile Food Operation (CMFO) for purposes of this document means an unenclosed mobile food facility that operates from a pushcart, pedal-driven cart, wagon, or other nonmotorized conveyance.

-

Food Compartment

means an enclosed space, including, but not limited to, an air pot, blender, bulk dispensing system, covered chafing dish, and covered ice bin, with all of the following characteristics:

- The space is defined by a physical barrier from the outside environment that completely encloses all food, food-contact surfaces, and the handling of unpackaged food.

- All access openings are equipped with tight-fitting closures, or one or more alternative barriers, that effectively protects the food from contamination, facilitates safe food handling, while minimizing exposure to the environment.

- It is constructed from materials that are nontoxic, smooth, easily cleanable, and durable and is constructed to facilitate the cleaning of the interior and exterior of the compartment.

-

Limited Food Preparation

means preparation that is limited to:

- Heating, frying, baking, roasting, popping, shaving of ice, blending, steaming or boiling of hot dogs, or assembly of non-prepackaged food.

- Dispensing and portioning of non-potentially hazardous food or dispensing and portioning for immediate service to a customer of food that has been held at the required temperatures.

- Slicing and chopping of non-potentially hazardous food or produce that has been washed at an approved facility.

- Slicing and chopping of food on a heated cooking surface during the cooking process.

- Juicing or preparing beverages that are for immediate service, in response to an individual consumer order, that do not contain frozen milk products.

- Hot and cold holding of food that has been prepared at an approved permanent food facility.

- Reheating of food that has been prepared at an approved permanent food facility.

- Potentially Hazardous Food (PHF) means a food that requires time or temperature control to limit bacterial growth or toxin formation. Examples include but are not limited to, tamales, sliced melons, burritos.

| MINIMUM REQUIREMENTS | Not handling raw meats, raw poultry, or raw fish | Handling raw meats, raw poultry, or raw fish |

|---|---|---|

| Health Permit | Yes | Yes |

| Plan Check Submission | Yes | Yes |

| Hand sink | Yes | Yes |

| Utensil washing sink | No, if there are adequate number of utensils | Yes |

| Water heater | No | Yes |

| Mechanical refrigeration for PHF | Yes | Yes |

| Commissary required | Yes | Yes |

This document can be used as part of the plan submission process for your proposed CMFO. You may draw your own plans using this document as guidance, but all items listed in this document must be represented in your submitted plans. Operators are required to have all plans approved prior to the construction of the CMFO to prevent any additional costs that would be incurred if modifications are needed should changes be noted on the plans. All items provided on the following pages are required unless otherwise noted.

- Submit one set of complete, easily readable plans that are drawn to scale.

- Drawings must show all four (4) sides and the top view of the CMFO and a complete plumbing diagram.

- Include equipment location on the drawing and submit a manufacturer specification sheet for all proposed equipment.

- Submit proposed menu or list of all items to be offered for sale.

- Submit completed plan check application and applicable plan check fee.

-

Once the CMFO plan review process is completed, and the CMFO is built per the approved plan, schedule a final inspection. At the final inspection be prepared to submit the following documents:

- Commissary/support unit agreement

- Written Operational Procedures

- Route Slip

- Once the CMFO is approved, a Public Health Permit application is to be submitted along with applicable fees to operate.

Please use the below checklist as a guide to assist you in the plan review process

| COMPLETED | ITEMS TO INDICATE ON PLANS |

|

|---|---|---|

| Each piece of equipment identified by manufacture and model and its location on the CMFO - All equipment must be an integral part of the CMFO | ||

| Table listing the material of finishes of the interior, exterior, and/or storage areas of the CMFO | ||

| Indicate equipment power source Battery Propane Tank | ||

| Location of the First Aid Kit | ||

| Location of 10 BC-rated fire extinguisher (required if electrical or gas equipment is used) | ||

| COMPLETED | SINK AND PLUMBING REQUIREMENTS |

|

| CMFO FOOD CART NOT HANDLING RAW MEATS, RAW POULTRY, OR RAW FISH | CMFO FOOD CART HANDLING RAW MEATS, RAW POULTRY, OR RAW FISH | |

Handwashing SinkAn integral handwashing sink with minimum dimensions: 9" wide X 9" long X 5" deep. Warm water not required. |

Handwashing SinkAn integral handwashing sink with minimum dimensions: 9" wide X 9" long X 5" deep. Warm water required. |

|

|

Utensil washing sink IS NOT REQUIRED if adequate number of spare clean utensils and cutting boards are provided.

Note: If there is built in food contact surfaces that cannot be easily replaced, such as a milk steamer nozzle, a utensil washing sink with hot water is required. |

Utensil washing sink

IS REQUIRED Each sink compartment must have minimum dimensions: 12" wide X 12" long X 10" deep OR 10" wide X 14" long X 10" deep. The utensil washing sink must be stainless steel and equipped with dual integral drainboards that are at least the size of one of the compartments. |

|

Potable Water Tank/Wastewater TankMinimum 5 gallons for handwashing with a minimum 7.5-gallon wastewater tank. |

Potable Water Tank/Wastewater TankMinimum 20 gallons required: 5 gallons for handwashing and 15 gallons for utensil washing Additional capacity is needed if product water is needed. All potable water tanks shall be manufactured and listed to NSF standards for potable water. Wastewater tank shall have a minimum capacity that is 50% greater than the potable water tank. |

|

Potable Water Tank/Wastewater TankMinimum capacity is 150% greater than the total capacity of provided potable water tanks. Where an ice bin is provided for storage, display or service of food/beverage, an additional holding tank capacity equal to one-third the volume of the bin must be provided. Multiple removeable tanks may be used. |

||

Water HeaterNot required |

Water HeaterHandwashing sink - a water heater with minimum 0.5-gallon capacity or an instantaneous heater is required and must be capable of supplying a minimum of 100°F running water.

Utensil washing sink - a minimum 4-gallon capacity water heater is required and must be capable of supplying a minimum of 120°F running water. |

|

| COMPLETED | ADDITIONAL REQUIREMENTS |

|

Plumbing LinesPotable water lines must be listed to NSF 61 for potable water. Waste lines cannot be the same color as the hoses for potable water. Typical potable water line colors are clear, white, or blue. Typical wastewater lines are black or grey. |

||

Water PumpPump for potable water supply must be listed to NSF standards. No pump will be approved for drainage. All liquid waste drainage must be done by gravity. |

||

| COMPLETED | EQUIPMENT |

|

Certified EquipmentAll equipment must be certified for sanitation.Note: 3rd party evaluations are accepted (e.g., NSF, ETL, CSA, UL, NEMKO, etc.) |

||

Mechanical RefrigerationRequired if holding or handling potentially hazardous foods, other than prepackaged ice cream or frozen fruit bars. Must be capable of holding food at or below 41°F. |

||

Hot-holding UnitRequired if hot holding potentially hazardous food. Must be capable at hot holding at or above 135°F. |

||

Separate storage compartments for clean and soiled utensils and storage for food or non-food items |

||

Food CompartmentTypical equipment requiring a compartment includes, but is not limited to: hot dog steamer, Italian ice serving freezer, fryer, griddle, and preparation area.Typical equipment NOT requiring a compartment includes, but is not limited to: espresso machine, microwave, ovens, air pots, blenders. |

||

| COMPLETED | ADDITIONAL REQUIREMENTS |

|

|

Name of Facility, City, State, and Zip Code of the permit holder affixed to the CMFO.

Lettering of the Facility Name: 3" high minimum |

||

| COMPLETED | DOCUMENTS TO BE INCLUDED WITH PLAN SUBMITTAL |

|

| Completed plan check application and applicable plan check fee. | ||

| Menu or list of all items being offered on the CMFO | ||

| Equipment manufacturer specification sheets for all proposed equipment | ||

LIST OF MENU/ITEMS BEING SOLD |

|---|

| Espresso, Lattes, Acai Bowl, Fruit Smoothies, Prepackaged Nutrition Bars, and Whole Fruit |

FINISH MATERIALS

*Raw wood not permitted to be used as exterior CMFO material

| LOCATION/EQUIPMENT | MATERIAL |

|---|---|

| Exterior of CMFO | Stainless Steel |

| Interior of CMFO | Stainless Steel/ Fiberglass Reinforced Panel (FRP) |

| Food Storage Area | FRP |

| Food Preparation Compartment | N/A |

| Other: | Exterior Vinyl Trim |

FOOD SERVICE EQUIPMENT LIST

| EQUIPMENT | MANUFACTURER | MODEL |

|---|---|---|

| Espresso Machine | Nuova Simonelli | Appia Life Compact2 |

| Blender | Vita Mix | 36019-ABAB |

| Undercounter Refrigerator | Bev-Air | UCR27HC |

| Coffee Brewer | Bunn | Axiom DV APS |

| Air Pots | Bunn | 32130.000 |

| Acrylic Prepackaged Food Display | Custom | Custom |

| Ice Bin with 2 Piece Lid | Moli International | BIB-1118-D 13” |

| Soap Dispenser | San Janmar | S30TBK |

| Paper Towel Dispenser | Bobrick | B-2620 |

POWER/GAS PLAN

Select all applicable options and fill in the blanks for each one:

- DC Battery* (Quantity 1 )

- AC Battery (Quantity )

- Propane Tank (Pounds ; Quantity )

*Requires Inverter

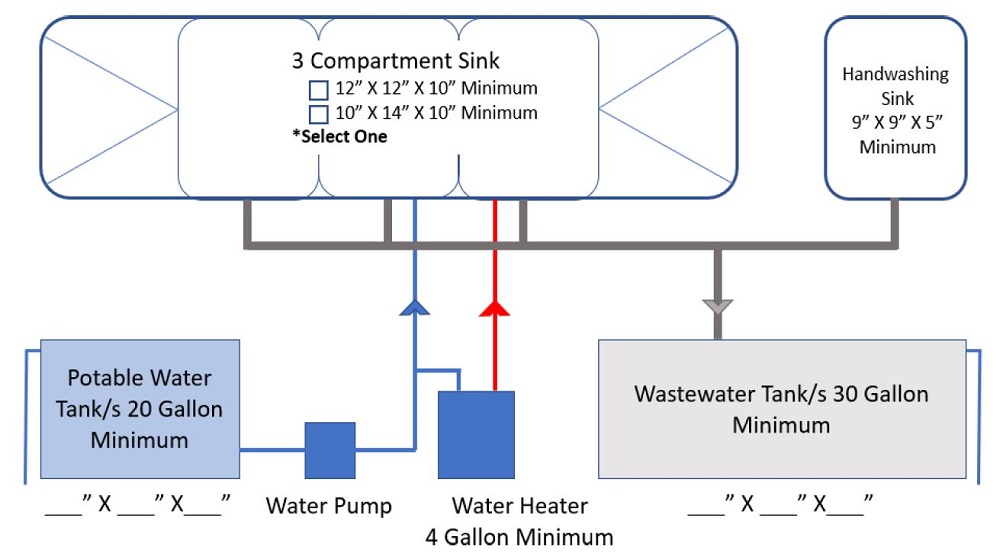

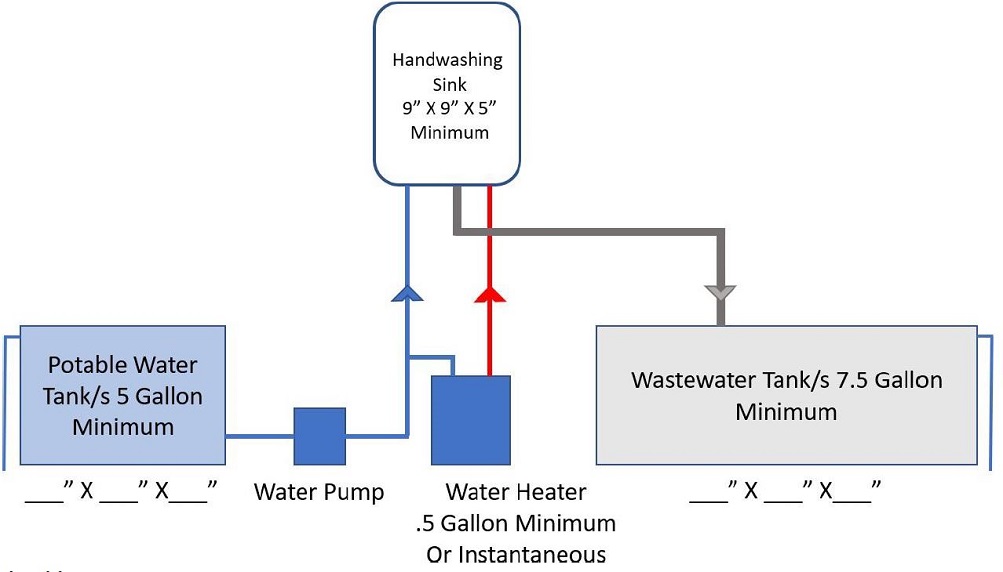

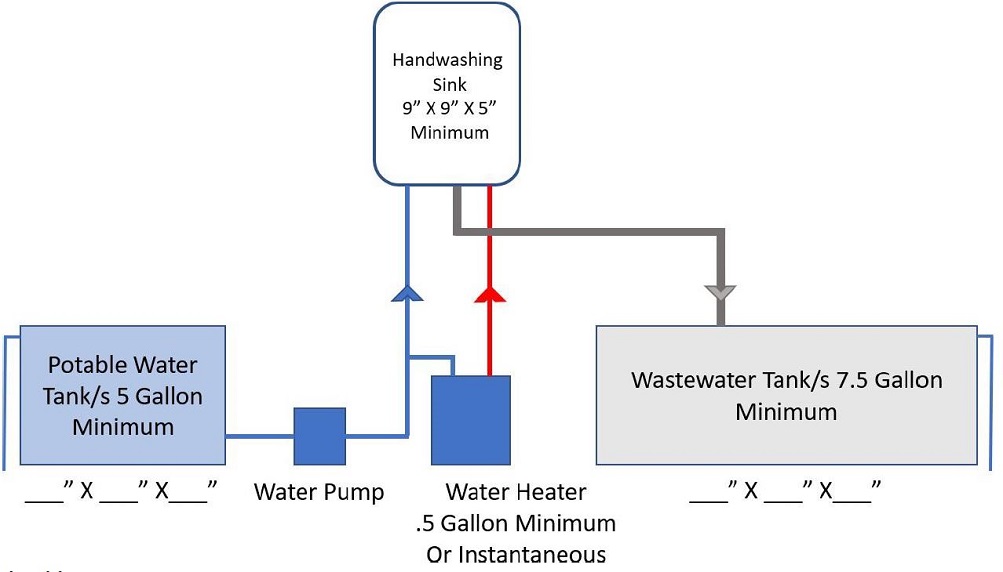

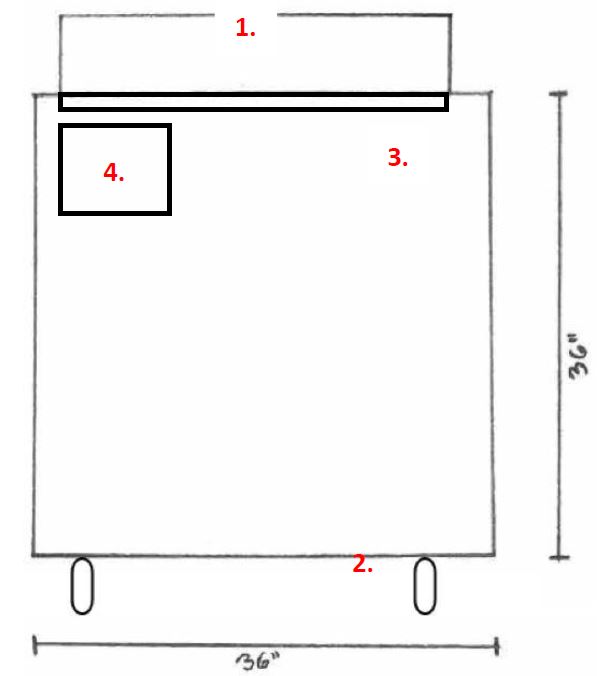

EXAMPLE OF PLUMBING DIAGRAM WITH 3 COMPARTMENT SINK

Plumbing Notes:

- Utensil washing sink provided to wash/sanitize permanently installed equipment which contacts food.

- All plumbing lines shall be connected to the tanks with watertight seals.

- Potable water lines, couplings, and valves shall be listed to NSF standards for drinking water.

- Potable water tanks and wastewater tanks mounted in the CMFO shall have an air ventoverflow installed draining outside of the CMFO in a downward direction covered with 16 meshper square inch screen.

- Tanks may be removeable. If they are not removeable, they must be equipped with a fill linethat has a nonthreaded quick disconnect coupler. They must also be installed sloped towards adrainage outlet equipped with a valve.

- Tanks and hose inlets and outlet fittings shall be protected with a cap and keeper chain, quickdisconnect, or closed cabinet when not in use.

- Waste lines must be a different color than the lines for potable water.

- The 3-compartment sink must be stainless steel and equipped with dual integral drainboardsthat are at least the size of one of the compartments.

WATER PUMP MANUFACTURER AND MODEL: _________________________________________

WATER HEATER MANUFACTURER AND MODEL: _______________________________________

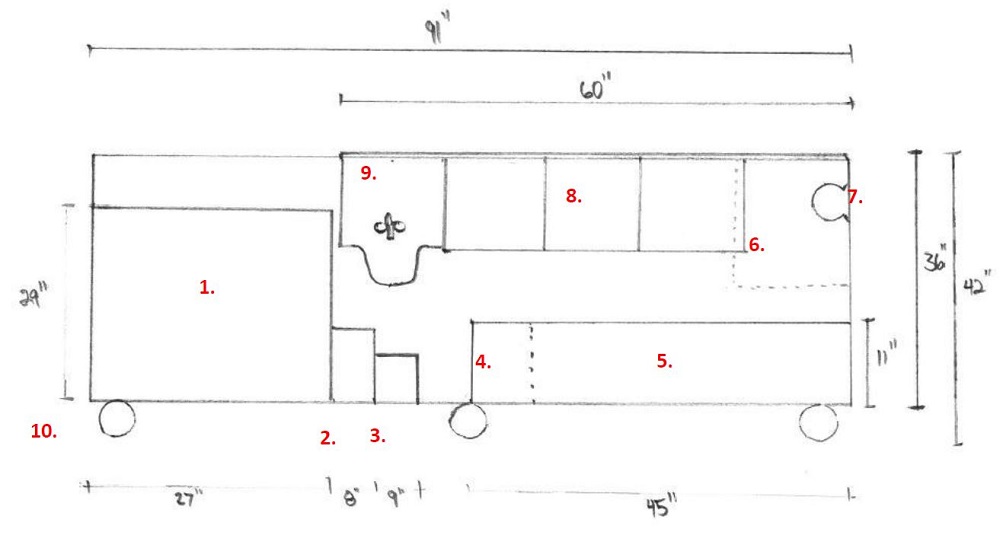

LEFT SIDE VIEW OF CMFO- Internal View Showing Location of the Equipment

- Refrigerator

- Battery, 12V 277 Amps

- Inverter

- 40 Gallon Wastewater Tank

- 20 Gallon Tank Potable Water Tank

- 6 Gallon Water Heater

- Water Pump

- 3-Compartment Sink

- Handwashing Sink with Soap and Paper Towel Dispenser

- 6" Swivel Casters

Scale: 1” = 1'

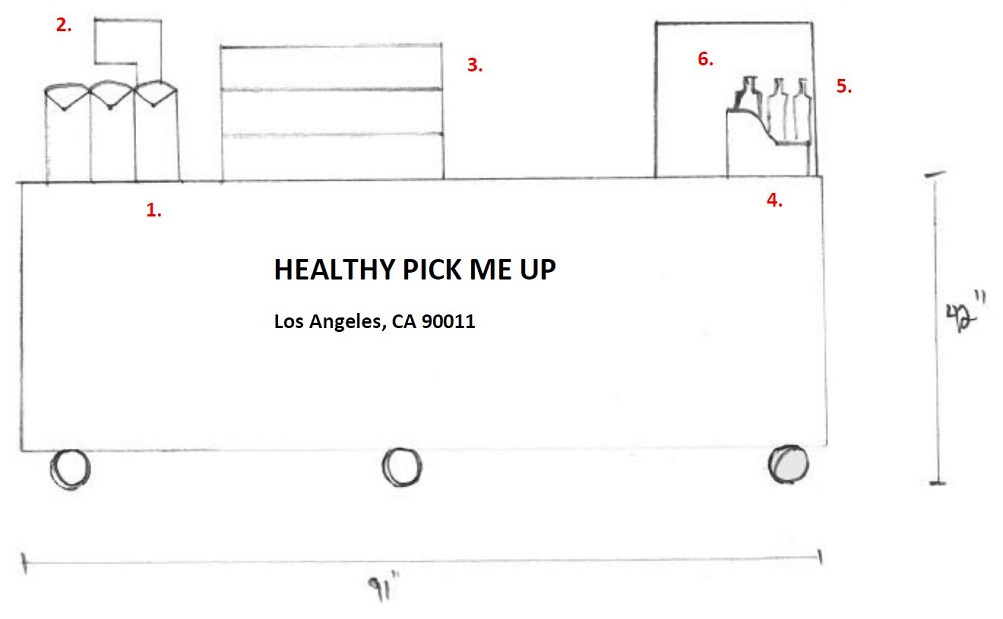

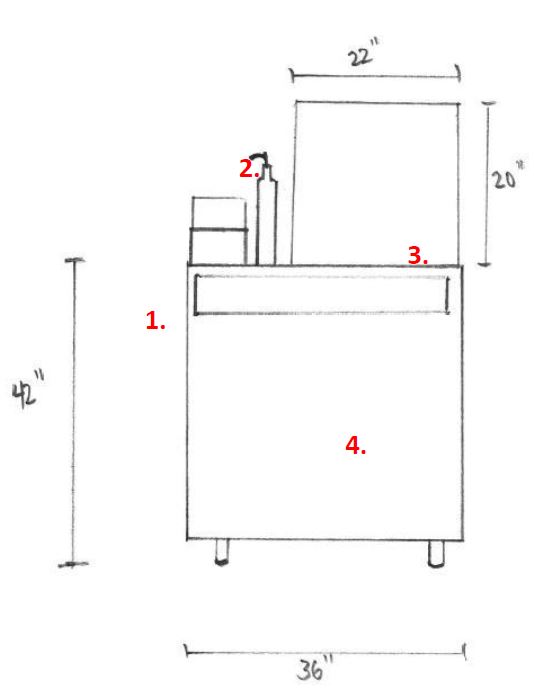

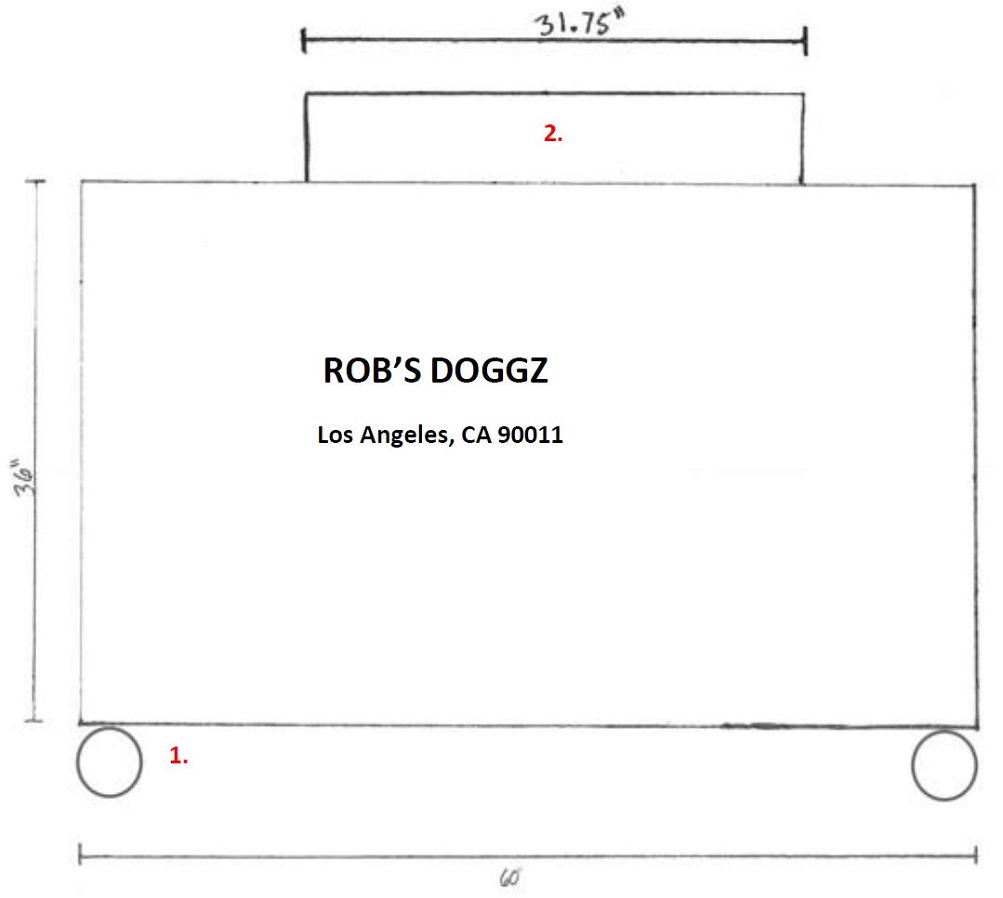

RIGHT SIDE VIEW OF CMFO- Showing Customer Side

- Airpot Coffee Dispenser

- Coffee Brewer

- Display Shelving

- Point of Sale- Register

- Flavored Syrup with Pumps

- Espresso Machine

*NOTE: Lettering of the business name: 3" high minimum

City, State, and Zip Code of the permit holder: 1" high minimum

Scale: 1” = 1'

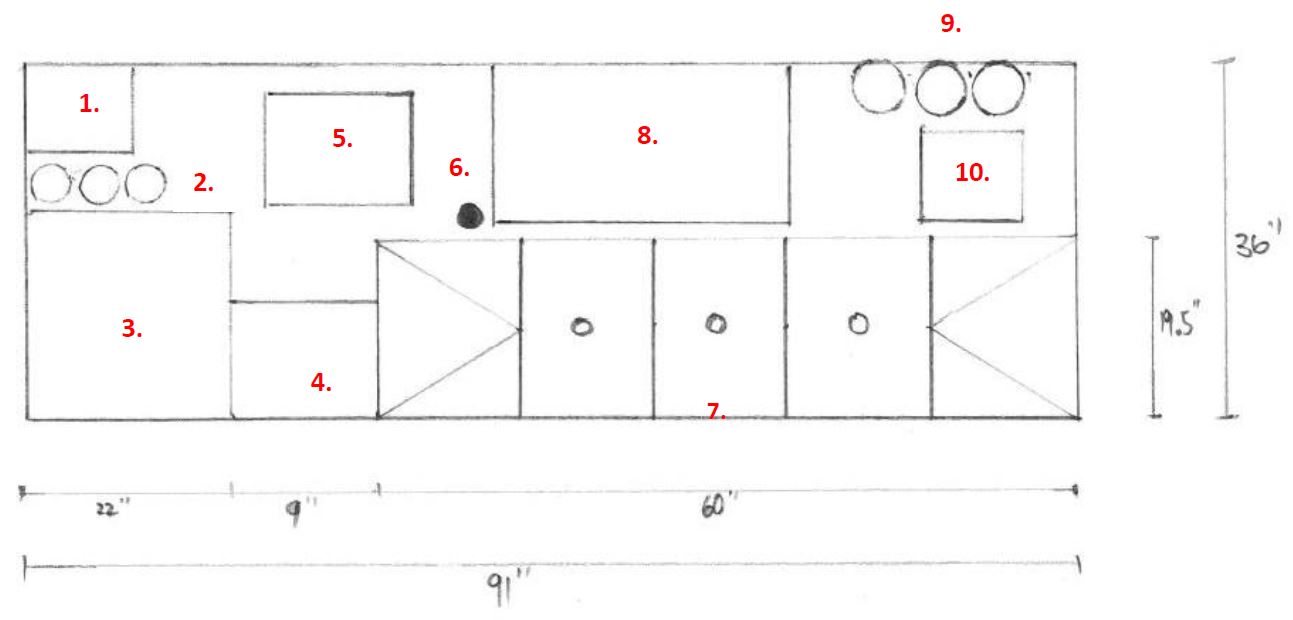

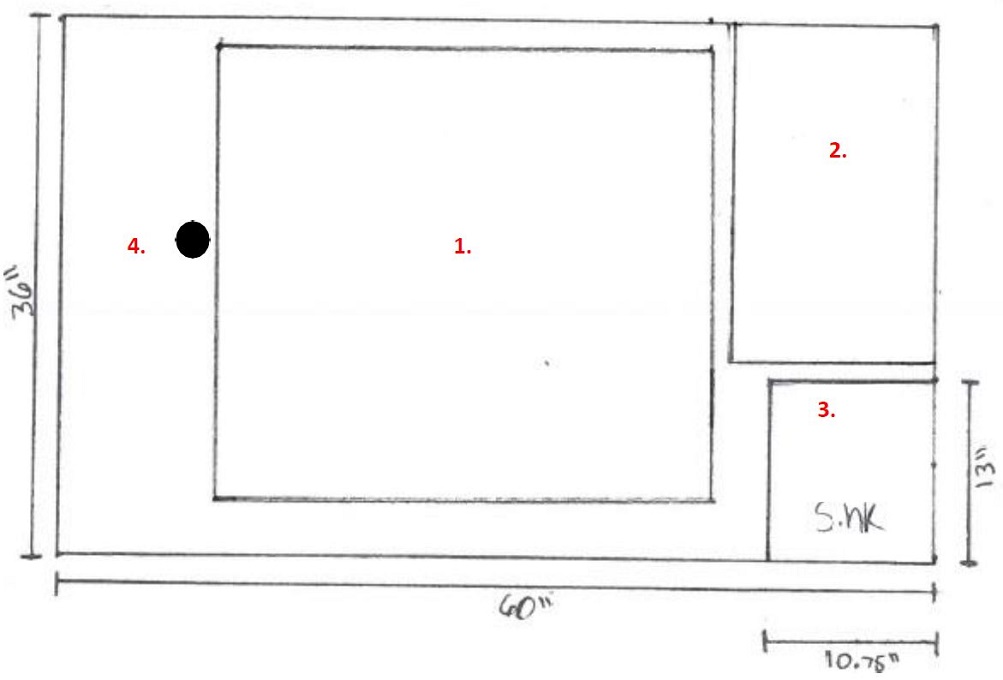

TOP SIDE VIEW OF CMFO

- Point of Sale - Register

- Flavored Syrup with Pumps

- Espresso Machine

- Blender

- Ice Bin with 2 Piece Lid

- Grommet for Umbrella

- 3-Compartment Sink

- Display Shelving

- Airpot Coffee Dispenser

- Coffee Brewer

Scale: 1” = 1'

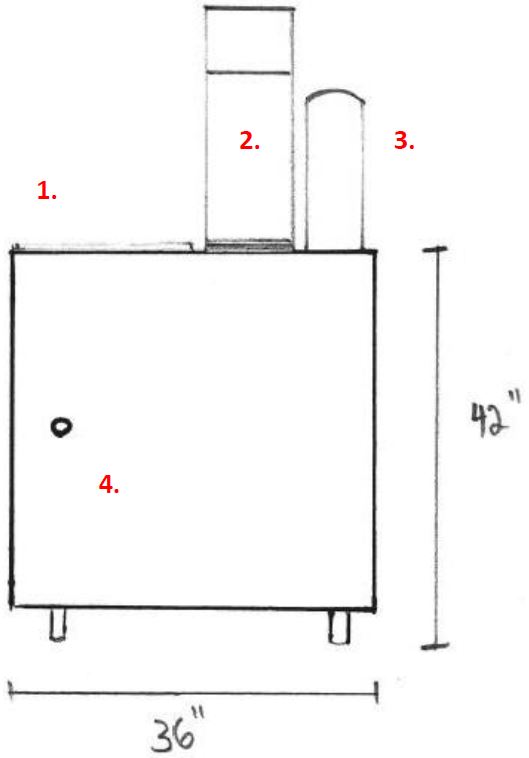

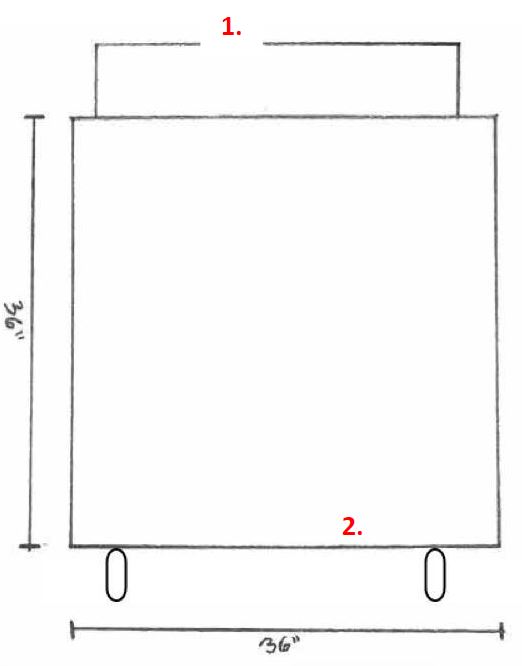

LEFT END FROM CUSTOMER SIDE VIEW OF CMFO

- 3-Compartment Sink

- Coffee Brewer

- Airpot Coffee Dispenser

- Quick Disconnect Potable Water fill with Chain and Cap

Scale: 1” = 1'

RIGHT END FROM CUSTOMER SIDE VIEW OF CMFO

- Point of Sale - Register

- Flavored Syrup with Pump

- Espresso Machine

- Cup Storage Area

Scale: 1” = 1'

LIST OF MENU/ITEMS BEING SOLD |

|---|

| Steamed Hot dogs, Prepackaged- Ketchup, Mustard, Relish, Mayonnaise (shelf stable), Canned Soda, Bottled Water |

FINISH MATERIALS

*Raw wood not permitted to be used as exterior CMFO material

| LOCATION/EQUIPMENT | MATERIAL |

|---|---|

| Exterior of CMFO | Stainless Steel |

| Interior of CMFO | Stainless Steel/ Fiberglass Reinforced Panel (FRP) |

| Food Storage Area | FRP |

| Food Preparation Compartment | N/A |

| Other: | N/A |

FOOD SERVICE EQUIPMENT LIST

| EQUIPMENT | MANUFACTURER | MODEL |

|---|---|---|

| Undercounter Refrigerator | Bev-Air | UCR27HC |

| Bun Warmer | APW Wyott | BWD-75N |

| Electric Steam Table | Wells | 5P-SS206-120 |

POWER/GAS PLAN

Select all applicable options and fill in the blanks for each one:

- DC Battery* (Quantity 1 )

- AC Battery (Quantity )

- Propane Tank (Pounds ; Quantity )

*Requires Inverter

EXAMPLE OF PLUMBING DIAGRAM WITHOUT 3 COMPARTMENT SINK

Plumbing Notes:

- Water heater is optional if no raw meats are handled.

- All plumbing lines shall be connected to the tanks with watertight seals.

- Potable water lines, couplings, and valves shall be listed to NSF standards for drinking water.

- Potable water tanks and wastewater tanks mounted in the CMFO shall have an air vent overflow installed draining outside of the CMFO in a downward direction covered with 16 mesh per square inch screen.

- Tanks may be removeable. If they are not removeable, they must be equipped with a fill line that has a nonthreaded quick disconnect coupler. They must also be installed sloped towards a drainage outlet equipped with a valve.

- Tanks and hose inlets and outlet fittings shall be protected with a cap and keeper chain, quick disconnect, or closed cabinet when not in use.

- Waste lines must be a different color than the lines for potable water.

WATER PUMP MANUFACTURER AND MODEL: _________________________________________

WATER HEATER MANUFACTURER AND MODEL: _______________________________________

LEFT SIDE VIEW OF CMFO- Internal View Showing Equipment Placement

- Refrigerator

- Bun Warmer

- Potable Water Tank

- Wastewater Tank

- Wastewater Tank

- Handwashing Sink with Soap and Paper Towel Dispenser

- Drop-in Steamer

- Water Heater

- Battery 12V, 277Amp

- Inverter

Scale: 1” = 1'

RIGHT SIDE VIEW OF CMFO - Showing Customer Side

- 6" Swivel Casters

- Bun Warmer

*NOTE: Lettering of the business name: 3"high minimum

City, State, and Zip Code of the permit holder: 1" high minimum

Scale: 1” = 1'

TOP SIDE VIEW OF CMFO

- Bun Warmer

- Drop-in Steam Table

- Handwashing Sink with Soap and Paper Towel Dispenser

- Grommet for Umbrella

Scale: 1” = 1'

LEFT END FROM CUSTOMER SIDE VIEW OF CMFO

- Bun Warmer

- 6" Swivel Casters

Scale: 1” = 1'

RIGHT END FROM CUSTOMER SIDE VIEW OF CMFO

- Bun Warmer

- 6" Swivel Casters

- Push Bar

- Paper Towel Dispenser

The following are some examples of the types of equipment that can be used to accomplish the code requirements.

-

All plumbing lines shall be connected to the tanks with watertight seals.

Watertight seal with attached ball valve on the side wall of a tank

Inside tank view of watertight seal

-

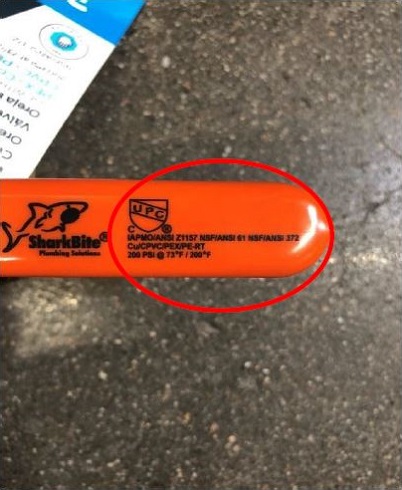

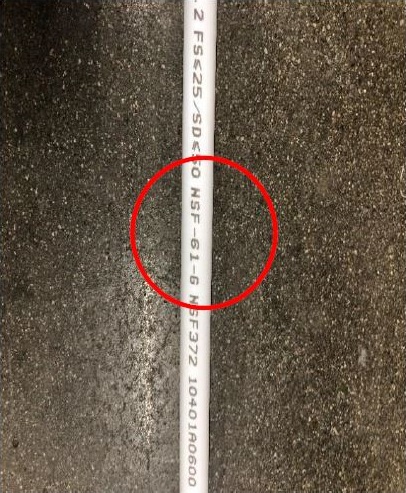

Potable water lines, couplings, and valves shall be listed to NSF standards for drinking water.

PEX Piping Ball Valve

ANSI/NSF 61 Label on handle

Straight Coupler with ANSI/NSF Label on bag

PEX Potable Water line with NSF-61 label

-

Potable water tanks and wastewater tanks mounted in the CMFO shall have an air vent overflow installed draining outside of the CMFO in a downward direction covered with 16 mesh per square inch screen.

Pipe with mesh

Typical mesh screens

-

Tanks may be removeable. If they are not removeable, they must be equipped with a fill line that has a nonthreaded quick disconnect coupler. They must also be installed sloped towards a drainage outlet equipped with a valve.

Fill line to non-portable tank with a quick disconnect coupler

Removeable portable tanks

Non-portable tank with connections to vent, fill, drain, and for the water pump

Removeable portable tank with quick disconnect for supply or wastewater (black lines typically denote waste)

-

Tanks and hose inlets and outlet fittings shall be protected with a quick disconnect

Quick disconnect coupler

-

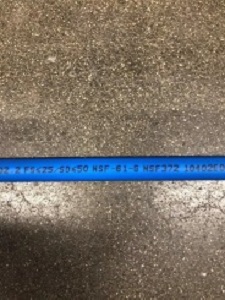

Waste lines shall not be the same color as the lines for potable water.

Potable white PVC line with NSF label

Non-potable/wastewater black PVC pipe

Blue potable PEX line with NSF label

Clear potable vinyl line with NSF